Why use low-consumption contactors in your motor control systems

Organizations are under more pressure than ever to improve sustainability metrics. How can you help them succeed — and win more business in the process?

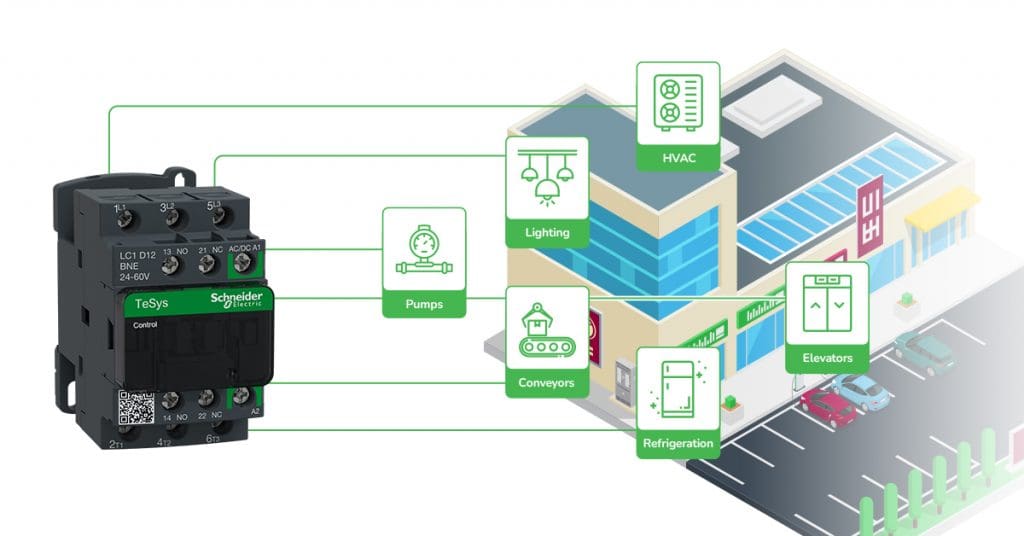

Building motor control systems with more sustainable parts is one piece of the puzzle. Control panel builders, system integrators, and design firms have an opportunity to deliver solutions that reduce CO2 emissions in tangible, measurable ways.

Increasing energy efficiency is a key method for decarbonization, contributing directly to reducing Scope 1 emissions. This area is prime for improvements across the electrical distribution landscape.

What is a low-consumption contactor and how does it work?

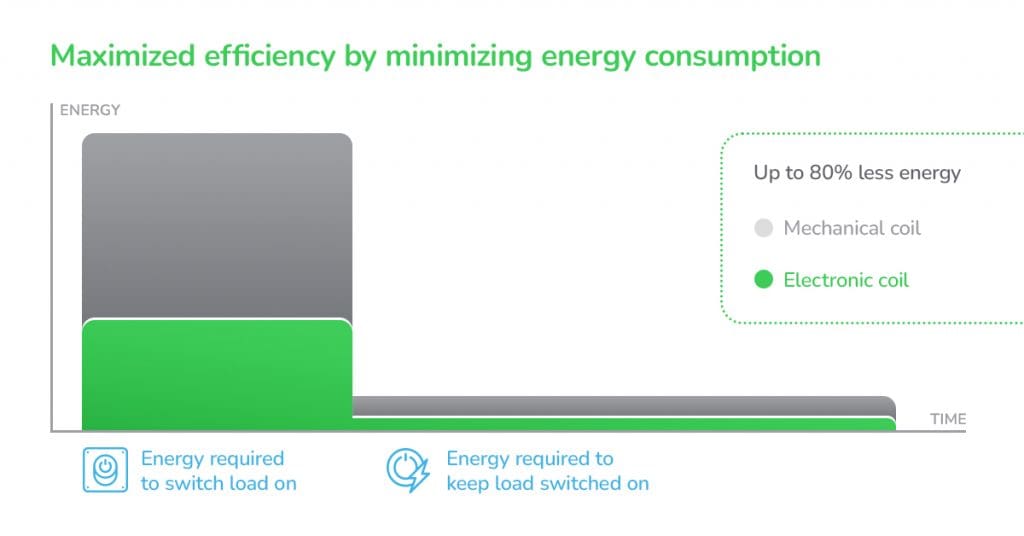

A traditional contactor uses an electro-mechanical coil to switch heavy loads on and off safely. But TeSysTM Deca Advanced contactors from Schneider Electric use an electronic coil with much higher efficiency. In fact, they use up to 80% less energy than traditional contactors for an immediate reduction in CO2 emissions.

This chart compares the energy use of TeSys Deca Advanced to TeSys Deca contactors that have traditional coils.

Get immediate and long-term reductions in CO2 emissions

- We seize opportunities to innovate and grow

- We are one firm with a shared sense of purpose

- We care about each other and the world around us

Improving sustainability is a focus for so many businesses today, but many find it challenging to produce measurable results and metrics to show their progress.

Using our TeSys Deca Advanced calculator allows you to find out just how much CO2 reduction you can help your customers achieve. Simply plug in the number of contactors your project requires (or that are in a customer’s existing facility that needs some modernization) to show:

- Current energy use

- Energy use if replaced with TeSys Deca Advanced

- Kg of CO2 emission reduction per year

Here’s an example: Imagine that a single plant operation uses (100) 9-40A contactors and (35) 50-80A contactors for a total of 135 contactors. Using the calculator, we find that over a 10-year period, your customer has a potential reduction of 4700 kg CO2 by just swapping this one electrical component. Repeat over the lifespan of their equipment and other operations, and you’ll see the energy savings start to add up.

Similar to swapping out traditional lights for LEDs as one part of a larger sustainability plan, using low-consumption contactors is a no-brainer.